Our primary concern has been and will always be ensuring the health and safety of employees and their families, along with our customers and suppliers. We quickly took steps to limit the impact of the global COVID-19 pandemic on our people and our operations.

In a matter of weeks, our employees completely redesigned the way we work while maintaining and even increasing productivity. We formed a cross-functional crisis response team to establish and implement new safety protocols across our businesses and to share best practices. We also found many ways to serve others and give back to our communities, which we have highlighted in the sidebars.

Ultimately, our employees navigated the challenges as a team, and we are a stronger company today because of their extraordinary efforts.

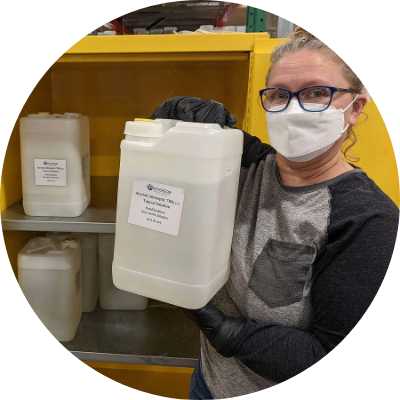

In just one week, Peterson Chemical Technology researched, developed formulas, obtained certification, and began producing hand sanitizer. PCT develops and produces specialty chemicals used to make foam.

In addition to being distributed within Leggett, the hand sanitizer has been donated to local schools, clinics, grocery stores, correctional facilities, and homeless shelters.